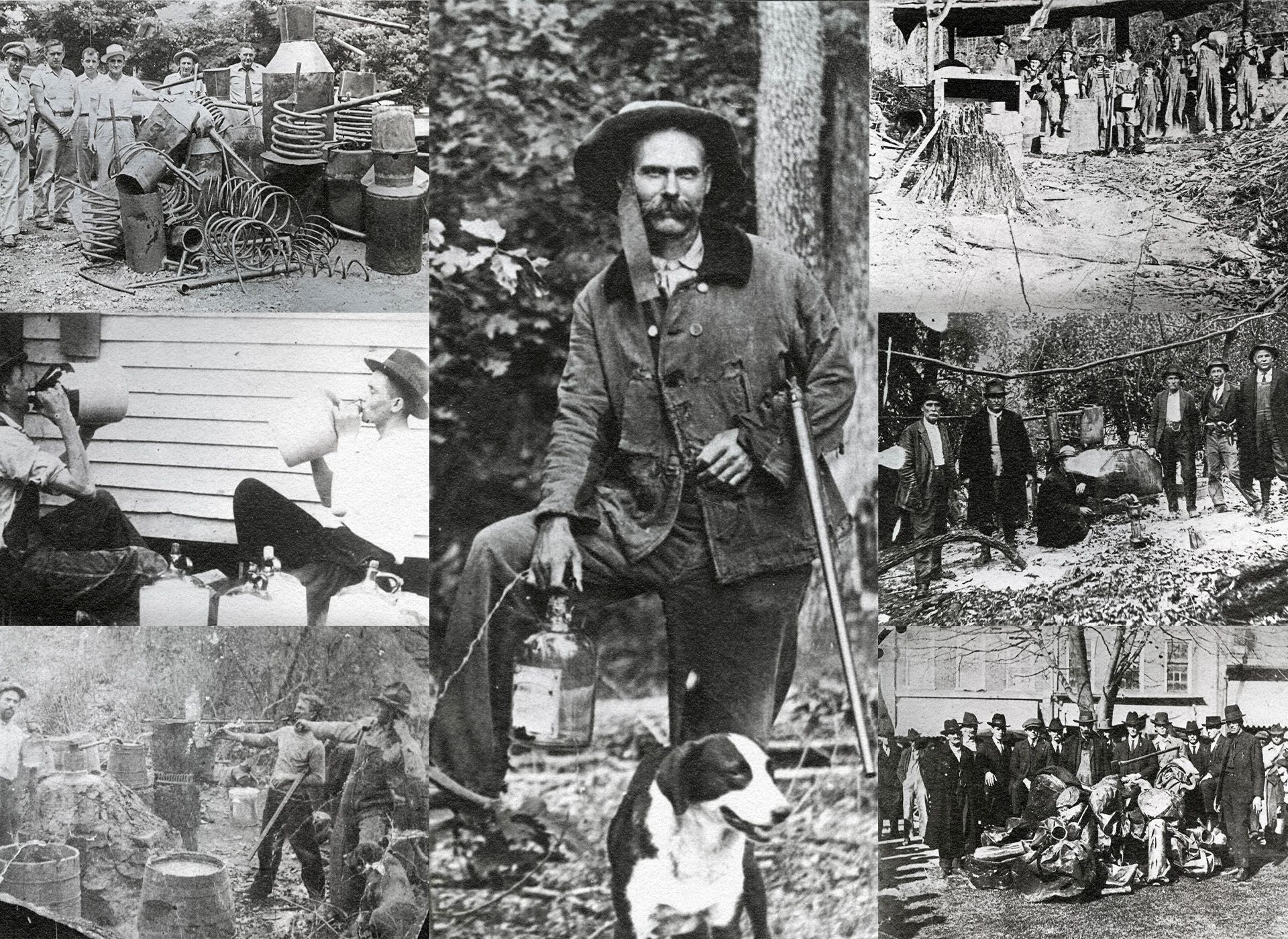

Modern Moonshinin' in Tennessee

Underground whiskey craft hasn't changed much the past hundred or so years

Whiskey became a natural byproduct for some of the earliest farmers in the states. Corn was a fast-growing native American crop, and early farmers soon found that they had much more than they could handle. As whiskey would take up less space, weigh less, and could be sold for a higher value as an artisan product, the market took off quickly. By 1790, Treasury Secretary Alexander Hamilton, looking for revenue for the fledgling United States of America, insisted that the federal government levy a tax on whiskey. And thus, the federal Whiskey Tax was born a year later—with big breaks for major distillers, of course.

Protests immediately followed. One day in 1791, excise officer Robert Johnson was on his collection route in Western Pennsylvania when eleven men dressed as women attacked him. Johnson was stripped, tarred, feathered, and had his horse stolen before being left in the woods. When he issued arrest warrants for the two men he recognized, the man sent with those warrants suffered the same fate—forcing Johnson to resign from his post. Things escalated until a year later, when President Washington assembled federal troops to march on the area. They arrested all suspected rebels and took them to Philadelphia for trial, where two were charged with treason only to eventually be given presidential pardons. Protests continued—in the form of tax evasion—throughout the states until 1802, when Thomas Jefferson repealed the tax alongside the Republican party. At this point, the money had been deemed nearly impossible to collect.

Later, during the Civil War, the Confederate government outlawed all whiskey production, hoping it would aid in fielding more troops. This period was when the term “moonshining”, or the process of distilling by the light of the moon, came into fashion. After the Civil War, the ban was lifted and distilleries cropped up so fast in response that there were hundreds statewide by 1908. Unfortunately, the boom didn’t last. Tennessee led the nation in prohibition, and distilling was banned again in 1910—ten years before the federal government instituted prohibition nationwide. “Moonshining'' remained the cultural standard until 1939, six years after the repeal of federal prohibition. At the same time, a statewide tax on transactions of distilled liquor was implemented. In part because of taxes like this, clandestine home distilling had firmly planted itself within the zeitgeist of the American South.

HOME DISTILLERS TODAY

There aren't that many differences between the home distillers of 1790 to 1939 and the home distillers of today aside from the technology. “Government officials are quite invested in heavily taxing certain substances,” notes Tore Olsson, Associate Professor of History at the University of Tennessee. “Often people, especially those in the mountains, are trying to get away from this kind of interference.” Both federal and state governments completely outlaw home distilling, but the law is nearly powerless in the face of the American tradition. The two men I spoke with have little concern for the legality of their hobby, and take pride in what they create. While many enjoy sharing product and even equipment, there isn’t much to be said for trading recipes—in the true spirit of American autonomy, everyone has their own special technique.

Moonshiners often have pseudonyms specific to the skill (to maintain anonymity), and “Tom Boggins” is no different. Boggins is a true homesteader: when we spoke, he was taking a short break from milling his own wood to use in a firewood barn. A born Nashvillian, Boggins learned each new skill he utilizes every day on the farm by himself, with only a collection of books for direction. Everything he does is driven by an “it can’t be that hard” gene deep within him, and whiskey distillation is no different. “It’s not that hard,” he laughs, “And if it is, who cares? It won’t be the second time.”

Within this framework, Boggins’ product doesn’t directly follow the guidelines for official whiskey or bourbon, and his still is similarly DIY in style. “I had a keg I couldn’t get the deposit back on after a party,” he explains. After he and some buddies had gotten together to gift a real still to their friend as a wedding gift, Boggins decided he would have his own. He turned that keg into a stainless steel still—adding on a couple of hot water heater elements—and he was in production. “Like any hobby,” he notes, “you can spend as much or as little money as you want on it.”

Of course, DIY is not without its occasional threats, and a good share of that labor becomes an educational experience. “Moonshining is kind of dangerous,” says Boggins, who once nearly combusted a rental home in his experimentation. “But anything can be dangerous if you’re an idiot.” Using an electric heating element in his still rather than an open flame not only alleviates some of that danger, but allows him to control the temperature of his mash exactly—an important practice to get quality whiskey. The “backslop,” or liquid leftover after being stripped of alcohol, will get reused in his next ferment. That process continues for up to about seven “generations” of liquor. Boggins’ pigs enjoy the remaining corn and sugar mixture.

His methods are simple, traditional, and relatively quick. Boggins first brews a “crude beer” with corn and sugar, putting that into his fifteen-gallon still. The first thing that comes out of a still is where the legend of moonshine making you blind comes from: lots of methanol, and little ethanol. Boggins will set this aside for cleaning or starting fires. After that, he’ll get about three gallons of what he calls “lowlines” on either end of the whiskey he keeps—this is liquid that has the ethanol he wants, but doesn’t taste quite perfect. Setting the best tasting hearts aside, the lowlines will be poured into his next batch for the still. This process is repeated in “stripping runs,” at high heat, until his final run stills at a much lower temperature. Identifying the hearts versus the lowlines, he explains, is all done by taste. He warns that the high proof of the liquor means dilution is necessary in the process: “You have to dilute it 50/50 with water or you’ll blow your taste buds out and make a bad run.”

Boggins distills in small amounts, and rather than aging traditional oak barrels, “oaks” his liquor in glass jars. Instead of oaky flavor entering the liquor over months of soaking in and out of a barrel, he roasts sticks of white oak at 400° for four hours, then gives them a char with a blowtorch, before dropping them in the jars with his liquid. This process is much faster, less expensive, and makes an old-fashioned American drink that tastes like whiskey. “People have been doing it forever not knowing what the science was, but still knew how to make it good,” says Boggins.

In contrast to Boggins, a home whiskey distiller I’ll call “Mark” has obsessed over that science. While he immediately mentions that “everything at the end of the day is moonshine,” Mark’s small runs of whiskey are made with “the rules” in mind. He is quick to explain to me that his whiskey is not bourbon, which must age for at least two years. Mark makes a great tasting, six month aged whiskey by using small, ten-liter oak barrels, explaining that the smaller barrel means his liquid has more surface area exposure to wood.

His experimentation was not without his own pitfalls. Mark started with a five-liter barrel for aging, and soon discovered the need to upsize. “I filled the barrel up, corked it, aged it six months, and when I opened it up there was nothing left,” he explains. What Mark was confronted with was a dramatic example of the “Angel’s Share”: as liquor soaks in and out of the barrel’s wood with changes in humidity, some portion of it evaporates. “The angels took all my liquor,” he laughs. From then on, it was a ten-liter barrel for aging.

For his still, Mark went with investment in his equipment, purchasing a twenty-gallon copper still. In a high quality run, he’ll end up with about two or three gallons of drinkable liquor, so he does two to fill his barrel. For his mash, Mark will use his own corn—the very same he feeds to his pigs, who like Boggins’ will enjoy leftover slop. Mark uses what is called a “thin mash,” which means ten gallons of grain, equal weight in sugar, and ten gallons of water. From there, the mash is heated until all of the grain sugars have dissolved into liquid. Once cooled, he casts his yeast and pours the mixture into a barrel with an airlock until it bubbles. This usually takes about three weeks, and Mark watches it with eager anticipation. “You keep waiting to see it bubble and all of a sudden it’s percolating, and that’s awesome,” he says.

Once that mixture is percolating, it has to be strained—a lot. Mark says this can be done with a “pillowcase over a five-gallon bucket.” If any corn kernels remain in the mixture, they’ll stick to the sides of his still, building so much heat that they can blow a hole straight through it. Like Boggins, Mark uses two thread holes for an electric water heater element in his still. Also like Boggins, Mark carefully collects and separates what comes out of his still in chronological order. That first bit of methanol, which he refers to as the “foreshots,” is easy to identify because “smells bad and tastes like absolute dammit.” He likes to set those aside to pour on the ground and set alight later, noting that “it makes the coolest flame.” After that is the first portion of his “lowlines,” which he calls the “heads”: about one and a half gallons of them. Then the sought after “hearts” (about twelve gallons on a good run) and finally the rest of his lowlines, “the tails” (another one and a half gallons, which will be cloudy in appearance). He collects this all in giant mason jars for separation and begins his aging process from there.

Mark is extremely proud of his creation. When he got together with some “good and seasoned whiskey drinkers” for a blind taste test where everyone brought their best product, he says most found that “at 101 proof this whiskey was way better in taste and in burn.” Up against some ten, twelve, and fourteen year aged liquor, he found that he had made a superior product in far less time by barreling it small and using better ingredients. “And, it’s also fun,” he chuckles.

He and his friends got into distilling around the same time, pitching in together for the equipment. They enjoy swapping jars with each other to see what each individual has come up with, but don’t feel the need to share recipes. This is the essence of the culture of homemade whiskey today, built on the same foundation as the whiskey hundreds of years ago: farmers and makers who share community, casually disregard regulation, and make something as American as apple pie. “I’m a fiddler, I’m a tinkerer. You could probably talk to someone who knows a lot more than me,” states Mark. “But I make a damn good whiskey.”